Case study

Case study

Case study

How the ii900 Acoustic Imager air leak detector can help you find the root cause of equipment issues and prevent costly downtime.

Case study

Read the wastewater plant case study on how the Fluke 3540 Power Monitor paid for itself in five months by eliminating the need to use contractors.

Case study

Watch the video to see how the Point Defiance Zoo and Aquarium uses the Fluke 438-ii power quality analyzer and motor analyzer to reduce water and energy . . .

Case study

Many facilities, such as power plants or production facilities, depend on a strong preventive maintenance program. These programs are essential to keep . . .

Case study

What if there were a leak detection technology that could pinpoint the precise location of a leak from up to 50 meters away? The Fluke ii900 Sonic Industrial . . .

Case study

Find out how air leak detection equipment prevents downtime for a 150,000 square foot plant that runs approximately 400 tools on compressed air, produced . . .

Case study

As the wind energy industry evolves, so does the wind technician community. Learn how a unique wind tech community shares troubleshooting and solutions . . .

Case study

Bob Despres of Jacobs Vehicle Systems® in Bloomfield, CT shares how he stepped up the motor maintenance program to be more proactive.

Case study

At the end of April 2005, Crystal Mountain Resort in Washington suffered catastrophic failure of two power filters associated with their chair lifts.

Case study

Maintenance electrical specialist Mark Newport was in the process of installing new electronic power factor correction units at multiple motor control . . .

Case study

You could almost call it a happy accident. During a routine job at a large industrial facility, an electrical maintenance worker set a plastic kit on top . . .

Case study

For three years in a row, a particularly large three-phase motor would fail twice a year. The facility maintenance manager called in both the electrical . . .

Case study

Ever fixed something and still not solved the problem? Sometimes multiple deficiencies can all cause the same symptoms.

Case study

Because power quality issues are difficult to pinpoint, clients often reach the wrong conclusions about their power issues. That often leads to expensive . . .

Case study

. . .

Case study

This case history comes from an electrical contractor. Several of this contractor's clients operate large commercial buildings.

Case study

Motor failures can be mysterious. Often, the mechanical loads on the motors have not changed and other loads connected to the same service appear to work . . .

Case study

Mac McArthur performs power quality studies for commercial, industrial, and residential clients.

Case study

After experiencing some nuisance tripping of breakers in the subpanel feeding the second floor of this industrial building, we installed a Fluke 1750 Power . . .

Case study

It was in his capacity as an electrical troubleshooter and an electronics expert that Gagne, almost two years ago, first began to use a Fluke 434 Power . . .

Case study

A ski resort near Silverthorn, CO., depends on its snowmaking capacity to augment nature's snowfall, especially during drought years.

Case study

This case history involves the investigation of a utility transformer failure that occurred in a rural area surrounded mostly by farmland and open space. . . .

Case study

One winter morning, the electrician received a call from a local school. The caller said a transformer supplying power to three portable classrooms was . . .

Case study

A small city gets its water from a mountain lake 30 miles away. A pumping system at the lake brings water up a short incline and into a long gravity pipeline . . .

Case study

The engineer carries a Fluke 43B on all trouble calls, because it provides a graphical display that allows customers to see a picture of the problem.

Case study

In most facilities, lighting is a major element of operating cost. Part of that cost is due to energy, and part is due to maintenance.

Case study

This case history is a classic example of the importance of a systematic approach to solving a problem. It involves a contractor who works with several . . .

Case study

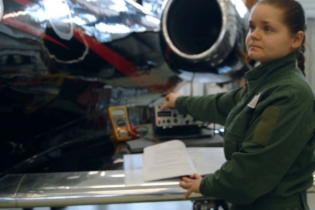

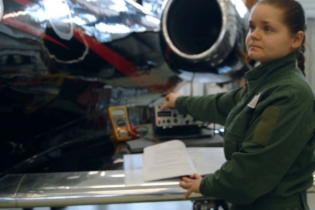

Driving the future of flight, Fluke tools are in the hands of the everyday heroes of aviation. Seppo Huittinen is an instructor at Savo Vocational College . . .

Case study

National Geographic details geysers, other hydrothermal features in production

Case study

Scientists collect a variety of critical information and data to better understand erupting volcanoes, including temperature measurements from handheld . . .

Case study

Filmwerks International is one company that has implemented a better way to monitor utility power for their backup UPS systems and generators

Case study

Benco Dental is the largest independent, family owned dental distributor in the United States, with more than 1,200 associates serving over 30,000 customers . . .

Case study

Electric fish, like knifefish, produce electrical signals used for sensing where they and their schoolmates are. Electric eels produce, in addition, more . . .

Case study

What's in your toolbox? Yuengling Tampa Brewery

Case study

The Yuengling maintenance team keeps the vintage facility brewing and bottling up to a million barrels of beer yearly. It takes a very lean operation to . . .

Case study

Every building, whether it houses commercial, industrial, municipal, healthcare, or educational operations, must include life safety systems.

Case study

Many services offered by ERS involve maintaining uninterruptible power supply (UPS) systems.

Case study

Ensuring that a soon-to-be-launched prototype printer works without any hiccups when it reaches consumer hands is an already daunting task. But when . . .

Case study

Downtime is costly, both in terms of patient wellbeing and monetary costs - the X-Ray, mammography, and other systems themselves cost millions and a . . .

Case study

MetalTech produces steel sheets. Maintenance technicians use the Fluke 1587 Insulation Multimeter to troubleshoot and maintain the equipment.

Case study

Learn how the Fluke ScopeMeter® 190-202 portable oscilloscope, used by scientist Will Crampton and the crew on location in Suriname to measure the voltage . . .

Case study

. . .

Case study

At commercial buildings and industrial plants, energy costs can quickly add up, especially when older lighting systems are in place, motors age and . . .

Case study

Astronomers from the University of New South Wales (UNSW) in Australia have been working in Antarctica's interior since 1996. In collaboration with . . .

Case study

A Canadian engineer keeps wind farm in New Brunswick up and running by using a Fluke multimeter.

Case study

The safety rated Fluke T+Pro gets field-tested by non-electricians. Larger buttons for gloved hands and a battery life indicator helped to make the . . .