It's just common sense that the higher the oscilloscope bandwidth, the higher the resolution of the results. The question is: How important is that in the day-to-day troubleshooting of most electricians and engineers?

It depends on your applications.

The wider the bandwidth and the faster the oscilloscope sample rate, the greater the accuracy and clarity of shape and amplitude of unknown waveform phenomena like transients, induced noise, and ringing or reflections. Those phenomena are showing up more often, due to the increased use of high speed electronic components in today's industrial controls, medical imaging, avionics, communications, military, and audiovisual and security equipment.

At least the fifth harmonic of a signal

Of course a device doesn't have to have a maximum clock speed of several hundred megahertz (MHz) to require a scope with wide bandwidth. A common rule of thumb is that to correctly display at least the fifth harmonic component of a signal, you need a scope with a bandwidth of at least five times the maximum clock rate of the device under test. That means if your device runs at a maximum of 100 MHz you need a 500 MHz scope to troubleshoot that device. Since most of that equipment has to be serviced in the field, a portable scope with 500 MHz capabilities is the only way to avoid the hassle of dragging an expensive and delicate bench scope to the location.

Fast edges

In addition, fast digital circuits, or inverter circuits that produce pulses with fast edges, contain an infinite spectrum of frequencies. To accurately capture and display these fast edges, you need a scope with a rise time that is less than one-fifth of the fastest rise time of the signal under test. The Fluke 190-502 ScopeMeter test tool with its 0.7 nano second rise time satisfies this requirement for a broad range of applications.

Practical application

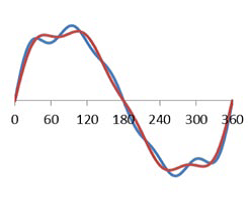

So what does this mean in practical application? Figure 1 illustrates the difference between an oscilloscope with a fast sample rate and a bandwidth of five times the fundamental and an oscilloscope with four times the fundamental. This screen shot compares two pulses: one that includes the 5th harmonic component and one with up to the maximum frequency of only the fourth harmonic component . As you can see, there is a significant difference in the displayed shape.

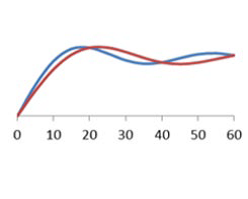

Figure 2 illustrates an additional comparison of rise time and signal slew rate between a measurement that includes frequency components up to the fifth harmonic and one that includes components up to the fourth harmonic.

So, with its 500 MHz bandwidth and fast sampling rate, the Fluke ScopeMeter™ 190-502 accurately captures and displays fast clock signals, including distortion-induced noise and spurious transients. As a result, it can make a significant difference in the speed and accuracy of troubleshooting high speed electronics components.