There’s no universal solution for all infrared inspections with a thermal camera, also known as a thermal imager. You need to match your method to the type of equipment you’re inspecting and the level of detail you require. That said, there are three typical methods that cover most situations you’ll run into:

- Baseline thermography

- Thermal trending thermography

- Comparative thermography

1. Baseline thermography

Baseline thermography is a good place to start for just about any application. First, you scan the equipment when it’s first commissioned or later in the lifecycle when it is working the way it should be, and then use that as a reference point for future inspections. Whether you compare the thermal images on your camera in the field, or on your PC using software tools, this baseline approach paves the way to helping you spot anomalies down the road.

2. Thermal trending thermography

Once you’ve set your baseline, you can use thermal trending inspections to compare how temperature is distributed in the same components over time. This can help you detect declining performance over time so that you can hopefully schedule downtime maintenance before equipment schedules it for you.

3. Comparative thermography

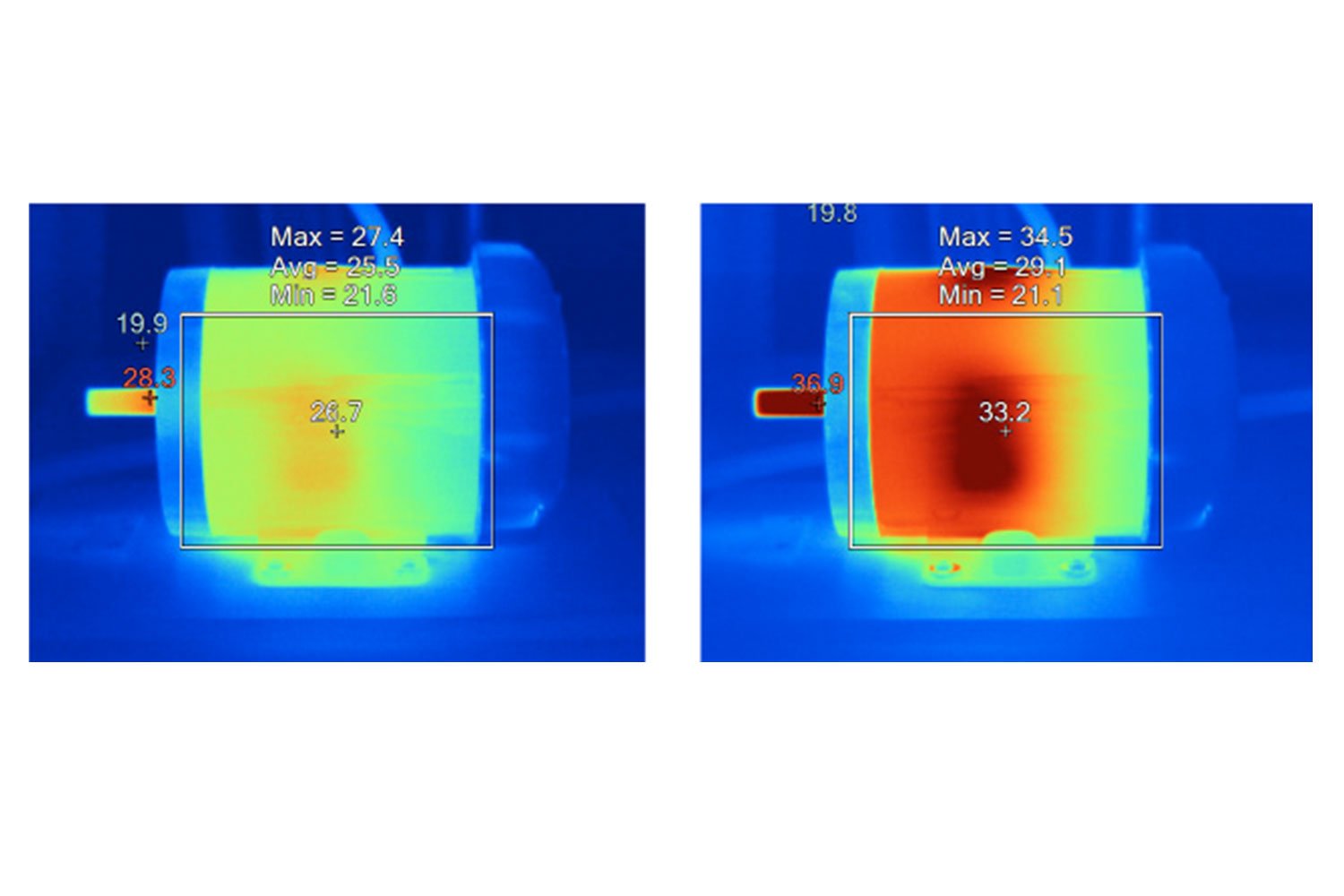

As you might expect, this means you scan similar components with your thermal camera under similar conditions and compare the results. This method relies on the idea that you expect similar or identical components, under similar loads, to have similar temperature profiles. Once you have three or more components it’s relatively easy to pick up an anomaly. Simple, right? Well, mostly. There’s one more level of complexity to consider: Depending on the components being compared, the actual temperature difference that can be considered an anomaly will vary.