Power quality: Analyzers, meters, recorders, loggers

Fluke power quality tools make it possible to identify your power quality and energy efficiency issues with easy and effective recording and analysis. Whether you’re trying to uncover hard-to-find intermittent problems, trying to find and eliminate reoccurring issues, or are interested in conducting load studies to discover potential savings. Fluke power quality tools enable you to quickly and easily take measurements when and where you need to. Flexible and powerful software is included with every Fluke power quality tool, allowing you visibility to valuable insights about the performance of your electrical system.

Find the best power quality tool for your needs

Whether you need to conduct an energy or load study, troubleshoot power quality issues, or record detailed power quality data Fluke has the right tool for you.

Fluke 1770 Series Three-Phase Power Quality Analyzers

Eliminate the complexities of three-phase power quality logging, troubleshooting, and analysis.

Fluke 1732 and 1734 Three Phase Power Measurement Logger

The Fluke 1732 and 1734 delivers easy to use three phase power measurements for identifying energy...

Fluke 1742, 1746 and 1748 Three-Phase Power Quality Loggers

Troubleshoot, quantify energy usage, perform quality of service surveys and create detailed reports...

Fluke 1736 and 1738 Three-Phase Power Quality Loggers

Versatile, three-phase Fluke Connect-compatible power loggers for conducting energy, load and power...

Fluke 1760 Three-Phase Energy Logger

The Fluke 1760 correlates multiple events, and provides undisputable verification in a Class-A...

Fluke PQ400 Electrical Measurement Window

The Fluke PQ400 gives you access to the critical power quality and energy data you need, all while...

Fluke VR1710 Single Phase Power Quality Recorder & Voltage Recorder

Detect and record parameters including RMS average, transients, flicker and harmonics with Fluke...

Fluke Norma 4000 Power Analyzers

Compact power analyzer. Take precision measurements of 1 or 3 phase current and voltage, harmonics...

Fluke Norma 5000 Power Analyzers

Highest accuracy 6-phase power analyzer. Measure voltage, current, and power harmonics.

Fluke Norma 6000 Series Portable Power Analyzers

Get accurate, precise measurements. Portable, lightweight power analyzer with 10 hours of battery...

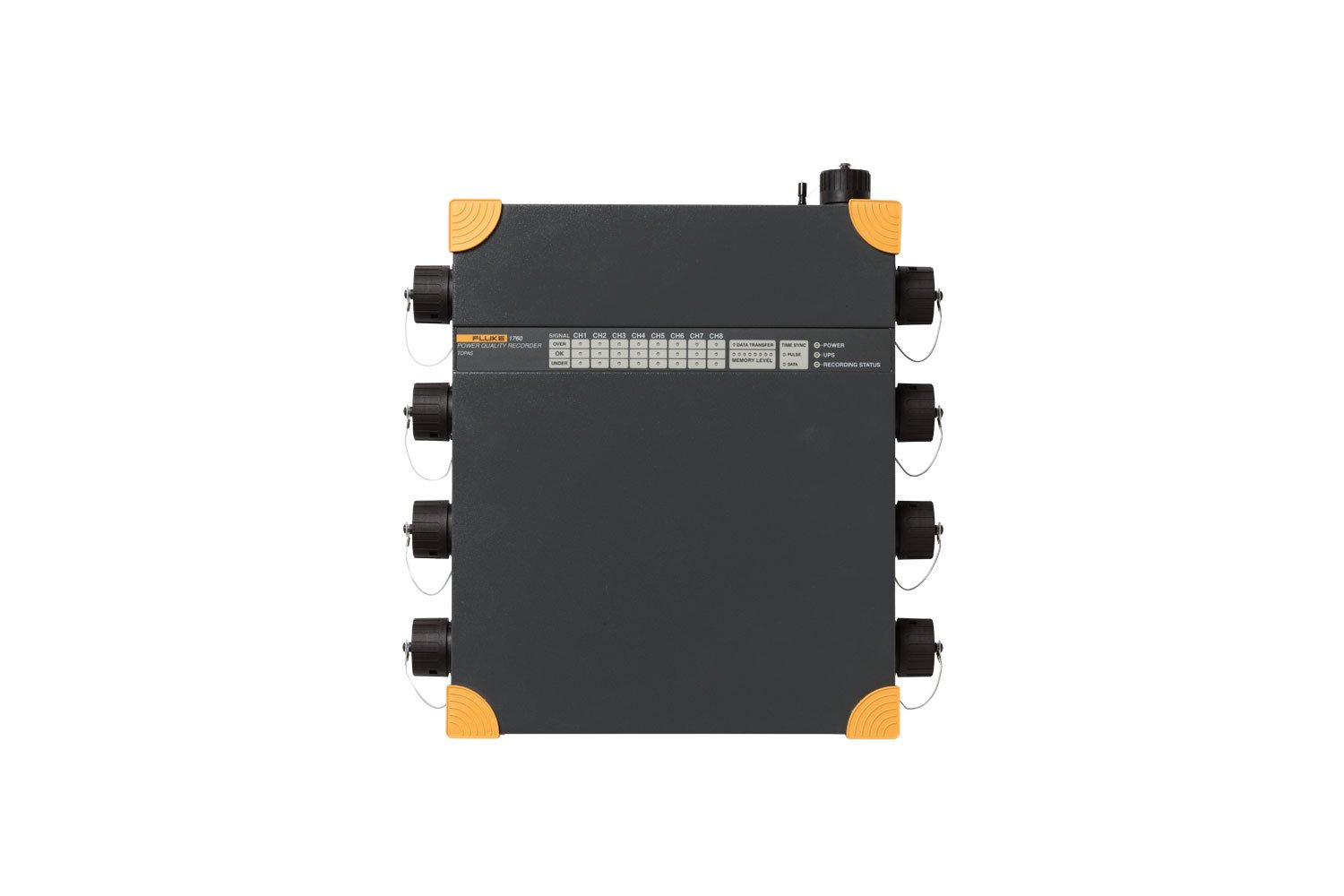

Fluke 1760TR Three-Phase Power Quality Recorder

Power Quality Monitor – Fluke’s three-phase power quality recorder is fully compliant to IEC...

Fluke 1760 Basic Three-Phase Power Quality Recorder

Power Quality Monitor – Fluke’s three-phase power quality recorder is fully compliant to IEC...

Fluke 1760TR Basic Three-Phase Power Quality Recorder

Power Quality Monitor – Fluke’s three-phase power quality recorder is fully compliant to IEC...

Chat with ourFluke assistant

Hi, I'm your virtual assistant, I will do my very best to help you navigate all things Fluke related. You can ask me anything! I'm new and might make a few mistakes. For safe use of Fluke tools, refer to the product manuals, safety sheets, and your company's safety requirements. To speak with a person, visit our Contact Us or Talk to Sales page. For information on how we handle personal data, see our Privacy Policy.