Fundamentals

Guide to Insulation Resistance Testing

A manufacturing line that goes down, even for a few seconds, could have a serious impact on production and to the bottom line.

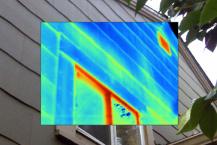

How to get great results with an infrared thermometer

Infrared (IR) thermometers enable you to measure temperature quickly, at a distance, and without touching the object you're measuring. They are so useful, . . .

Most common causes of machine vibration

Vibration can result from a number of conditions, acting alone or in combination. Keep in mind that vibration problems might be caused by auxiliary . . .